We have 8 modern production lines, the world's most advanced equipment; 150 modern stamping equipment; 500 sets of multi-metal molds; annual output of 10 million cans. We have much professional technical staff to arrange the entire production process from procurement, printing, cutting, manufacturing, packaging to shipping, etc. We put quality first, treat customers as the supremacy, and provide high-quality packaging products and services to customers from all over the world. Our goal is to become the largest professional tin box manufacturer in China and serve our customers wholeheartedly. Let us create a brilliant tomorrow with our customers.

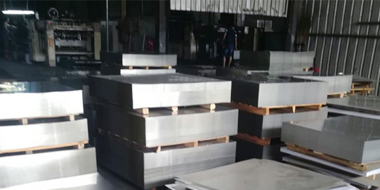

Generally, after confirming the order, tinplate metal will be ordered according to product’s specifications. Tinplate is a steel plate electrolytically coated with a fine layer of tin for protective purposes. Tinplate is a high quality safe packaging material for food items such as cookies, candies, chocolate, etc. Food grade lacquer is coated on the inside […]

Printing is done on a large metal sheet by a large printing machine and it is an offset printing process utilizing CMYK colors. In the printing process, it is necessary to pay attention to whether the printed color, as well as positioning, are consistent, Whether there are stains, whether there are scratches, etc. These issues […]

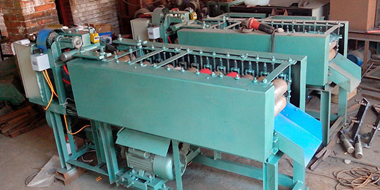

After completing the printing process, large printed metal sheets will be slit into small pieces for stamping and formation.

The small metal sheet needs to be formed into shape by molding on the machine. This is the main and important process of producing a tin box. This process is split into many small processes.

Finished tin box will be cleaned by medical alcohol and passed through oven before going into the carton.

After stamping, the packaging department is responsible for cleaning and assembling, putting in plastic bags, and packing. This link is the final work of the product. The cleaning of the product is very important, so the work must be cleaned before packaging, and then packaged according to the packaging method. For products with many styles, […]